diff --git a/README.md b/README.md

index 97eb061..47c3348 100644

--- a/README.md

+++ b/README.md

@@ -7,7 +7,8 @@ Watch my YouTube video about it: https://youtu.be/hq53gsYREHU

# Important Notes

-In its current for it only works with G-Code files generated with CURA due to the comments CURA puts into the G-Code files.

+In its current for it only works with G-Code files generated with CURA, Prusa, Bambu and Orca Slicer due to the comments the slicer puts into the G-Code files.

+In the "Universal" folder is the script compatible with all of the mentioned slicers and detailed instructions.

It is also important to make sure that the "Walls" are printed before the "Infill" ("Infill before Walls" OFF).

For this script to work, also activate "Relative Extrusion" under "Special Modes".

@@ -39,3 +40,6 @@ Add a gradual speed variation for machine without direct drive extruder.

Sample part with a Gradient distance set to 8 mm :

+

+# GradientInfill by WatchingWatches

+Adapted version of the script addGradientInfill.py, which works with Prusa, Bambu, Cura and Orca slicer. The universal_addGradientinfill.py script automatically recognizes the slicer. The script has a own folder: Universal, with a Readme. Also Check the different branches for beta releases with new features.

\ No newline at end of file

diff --git a/Universal/README.md b/Universal/README.md

new file mode 100644

index 0000000..bea4858

--- /dev/null

+++ b/Universal/README.md

@@ -0,0 +1,110 @@

+# Gradientinfill for Orca, Bambu, Prusa and Cura slicer:

+

+If you are running the script from the slicer there will be just one output file. I recommend testing the script first inside of an IDE and compare the original and modified file.

+

+The following part was originally written as a guide for prusa slicer, but the slicer settings are the same, but might be found at a different location with a slightly different name.

+

+## Introduction what changed?:

+

+This is a fork of the repository of CNC-Kitchen. I didn't change the working principal of the script. I mainly adapted the comments within the gcode file to suit those generated by Orca, Bambu and Prusa slicer and changed a few things which resulted in errors previously (used re patterns instead of searching for single characters in line).

+I implemented an volumetric flow limit and other minor improvements. The script can recognize, which slicer generated the gcode and works with Orca, Bambu, Prusa and Cura slicer. There is also a option to reduce the line width in the core with `THIN_INNER_CORE: bool = True`.

+To understand better how the script works, I recommend watching the YouTube video and reading the README.md in the main folder. There you can also find instructions to install python (I'm using python 3.9.18 with the anaconda distribution).

+

+### Example:

+

+In the pictures you can see the change in line width, which was the original function. When you increase the line width, but don't change the print speed you will increase the volumetric flow, which can be too much for your hotend. I implemented a flow limit, which decreases the printing speed when the flow is getting too much (18 mm^3/s in the example). The maximum velocity is set by the initial velocity.

+

+

+

+

+

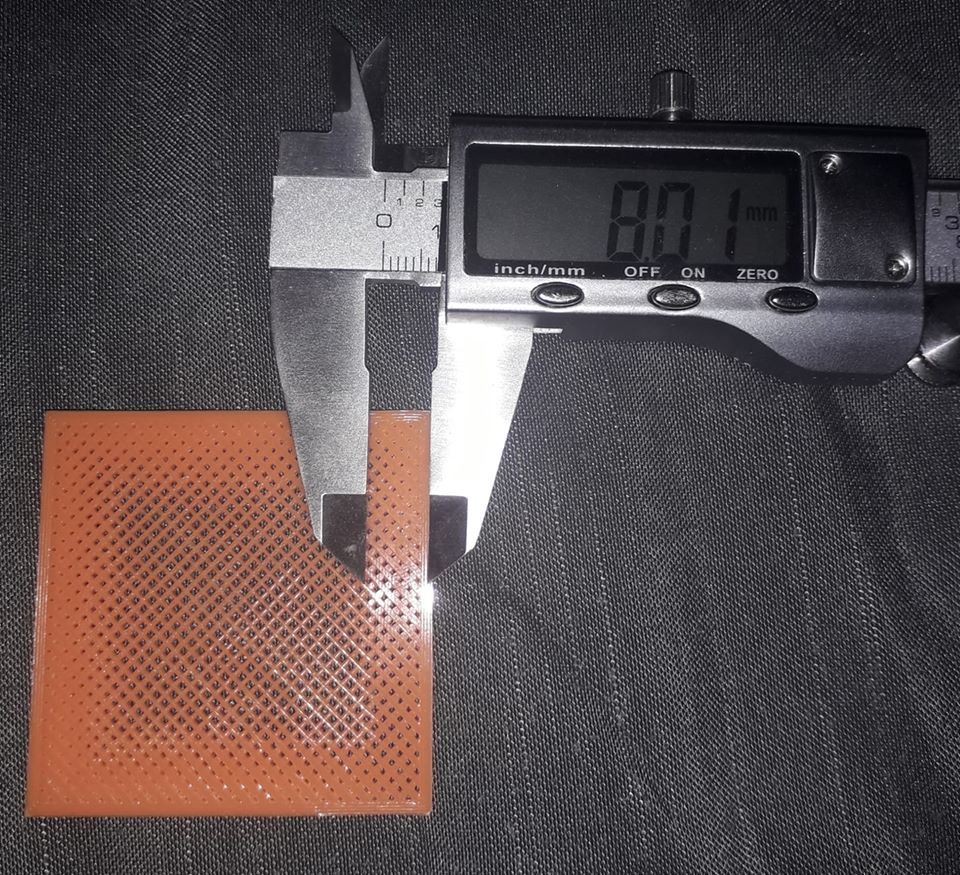

+Here you can see it applied in a real print:

+ +

+### Unclean extrusion:

+

+Often times Infill generates lines, which look like perimeters. The problem is, that there is no space for the line to expand to, like in the core of the Infill.

+This results in unclean extrusions, which have an increased height, which results in marks on the top layers. To fix this, lines which are nearly collinear to the perimeter (small angle) don't get modified and stay at their original width.

+The feature currently only works with `SMALL_SEGMENTS`.

+

+

+

+### Unclean extrusion:

+

+Often times Infill generates lines, which look like perimeters. The problem is, that there is no space for the line to expand to, like in the core of the Infill.

+This results in unclean extrusions, which have an increased height, which results in marks on the top layers. To fix this, lines which are nearly collinear to the perimeter (small angle) don't get modified and stay at their original width.

+The feature currently only works with `SMALL_SEGMENTS`.

+

+

+  +

+  +

+

+

+## Features:

+

+- The script can be called directly after slicing with an optional dialog in the terminal, which will automatically open (`dialog_in_slicer: bool = True`)

+- It's also possible to run the script inside of an IDE (it automatically detects, if it's inside of an IDE)

+- If the script didn't do any changes it will print a message. This means something went wrong

+- If a bug occurs the error message will be written inside of the terminal. When this happens please review, that all of the entered settings are correct. Open an issue here at this repository and share your gcode and/or 3mf file with settings and the error message to get help

+- Automatically find relevant settings from gcode (line width, Infill pattern, maximum volumetric flow)

+- The script stops if G2/3 moves are detected, which are not supported

+

+## Slicer settings (enable advanced mode):

+

+Without these slicer settings the script will not work.

+

+### Disable Arc fitting in print settings-> advanced:

+

+![arc fitting]()

+

+### Use relative extrusion in printer settings-> general:

+

+![Relative extrusion]()

+

+### Infill before perimeter need to be turned off printer settings-> infill:

+

+

+

+### Wipe while retracting must be disabled:

+

+printer settings -> extruder -> retraction

+

+Also ensure, that the filament override is disabled.

+

+### Automatically call script when saving the file:

+

+

+

+Insert the path to your python.exe followed by the path to the python script in print settings -> output options.

+Not possible with Cura use the script of 5axes instead for slicer integration. If you want to use my new features run the script from an IDE.

+

+## Running script:

+

+The script gets called after the slicing process.

+This means, that the preview inside of the slicer doesn't show the changes of the script.

+

+### Investigate the modified gcode (recommended):

+

+The following steps are recommended and should be performed every time, until you trust the script. There might be errors specific to your gcode, which I haven't thought of. Those could potentially damage your printer.

+

+Open the file inside of a gcode viewer (drag the gcode file into a slicer/gcode previewer [Prusa works well]), to take a look at the modified gcode. Select the line width color scheme to see the difference.

+Open the two files inside of notepad++ and compare both files with a plugin called "compare". The program will mark all of the changes in between both files. This is the safest check, since the gcode previewer can give a wrong impression (use a small file).

+

+## General advice:

+

+Experiment with the different parameters. For me a `MAX_FLOW = 350` was set too high and 250 worked better.

+

+Print small test pieces to test your settings. The test pieces don't need to be tall, but the infill section needs to be large enough, so you can actually see the difference in line width.

+You may need to lower the infill speed, since the flow increases with the use of the script (the volumetric flow limit within the script can makes this step obsolete if it works correctly).

+Check in the preview, that it's not exceeding the maximum flow of the hotend. The line width of the infill shouldn't be much higher than the nozzle diameter in the slicer setting.

+

+When you look at the second picture you can see that the flow in the inner core (outside of the `GRADIENT_THICKNESS` range) isn't changed. If you want a thin infill width in the core (where the forces are the lowest) you can enable `THIN_INNER_CORE: bool = True`.

+

+If you modify a big file the computing time can be several minutes long.

+I tried adding a progress bar, but it nearly doubled the execution time, so i removed it.

+

+## Personal recommendation:

+

+You can decrease the run time by using a special interpreter called pypy. For large files it decreased the run time by x7 (may differ on your machine). [Here is an installation guide.](https://doc.pypy.org/en/latest/install.html)

+

+## Prospect for the future:

+

+I will try to optimize the calculation time of the script.

+With your help i will debug the script for errors, which might occur.

+The next step will be adding an automatic infill pattern recognition.

+

+You may also be interested in [my own postprocessing scripts.](https://github.com/WatchingWatches/Post_processing_gcode).

+

+Thank you for you feedback in advance. Also feel free to adapt the script to other slicers too.

diff --git a/Universal/pictures/Flow.png b/Universal/pictures/Flow.png

new file mode 100644

index 0000000..e7d46e1

Binary files /dev/null and b/Universal/pictures/Flow.png differ

diff --git a/Universal/pictures/IMG_20240321_223411411.jpg b/Universal/pictures/IMG_20240321_223411411.jpg

new file mode 100644

index 0000000..2102c5b

Binary files /dev/null and b/Universal/pictures/IMG_20240321_223411411.jpg differ

diff --git a/Universal/pictures/Screenshot 2024-03-21 231928.png b/Universal/pictures/Screenshot 2024-03-21 231928.png

new file mode 100644

index 0000000..51c0b03

Binary files /dev/null and b/Universal/pictures/Screenshot 2024-03-21 231928.png differ

diff --git a/Universal/pictures/Screenshot 2024-03-21 232256.png b/Universal/pictures/Screenshot 2024-03-21 232256.png

new file mode 100644

index 0000000..99f22c1

Binary files /dev/null and b/Universal/pictures/Screenshot 2024-03-21 232256.png differ

diff --git a/Universal/pictures/Speed.png b/Universal/pictures/Speed.png

new file mode 100644

index 0000000..7ebde04

Binary files /dev/null and b/Universal/pictures/Speed.png differ

diff --git a/Universal/pictures/Width.png b/Universal/pictures/Width.png

new file mode 100644

index 0000000..e1fe048

Binary files /dev/null and b/Universal/pictures/Width.png differ

diff --git a/Universal/pictures/example_print.jpg b/Universal/pictures/example_print.jpg

new file mode 100644

index 0000000..77254d9

Binary files /dev/null and b/Universal/pictures/example_print.jpg differ

diff --git a/Universal/pictures/gcode_preview.png b/Universal/pictures/gcode_preview.png

new file mode 100644

index 0000000..f3a0c0c

Binary files /dev/null and b/Universal/pictures/gcode_preview.png differ

diff --git a/Universal/pictures/image-1.png b/Universal/pictures/image-1.png

new file mode 100644

index 0000000..0771947

Binary files /dev/null and b/Universal/pictures/image-1.png differ

diff --git a/Universal/pictures/image-2.png b/Universal/pictures/image-2.png

new file mode 100644

index 0000000..75082f2

Binary files /dev/null and b/Universal/pictures/image-2.png differ

diff --git a/Universal/pictures/image.png b/Universal/pictures/image.png

new file mode 100644

index 0000000..4d1f4a9

Binary files /dev/null and b/Universal/pictures/image.png differ

diff --git a/Universal/pictures/infill_near_wall.png b/Universal/pictures/infill_near_wall.png

new file mode 100644

index 0000000..6f50682

Binary files /dev/null and b/Universal/pictures/infill_near_wall.png differ

diff --git a/Universal/pictures/unclean_extrusion.jpg b/Universal/pictures/unclean_extrusion.jpg

new file mode 100644

index 0000000..b776f47

Binary files /dev/null and b/Universal/pictures/unclean_extrusion.jpg differ

diff --git a/Universal/universal_addGradientinfill.py b/Universal/universal_addGradientinfill.py

new file mode 100644

index 0000000..aa404bc

--- /dev/null

+++ b/Universal/universal_addGradientinfill.py

@@ -0,0 +1,737 @@

+#!/usr/bin/env python3

+"""

+Gradient Infill for 3D prints.

+Orca, Bambu, Prusa slicer

+

+License: MIT

+Author: Stefan Hermann - CNC Kitchen

+Fork Author: Benedikt Jansson - WatchingWatches

+Version: 1.0

+"""

+import re

+import sys

+from collections import namedtuple

+from enum import Enum

+from typing import List, Tuple

+import traceback

+import time

+from math import pi, degrees, acos

+

+

+__version__ = '1.0'

+

+"""

+

+Only accepts G1/G0 commands and relative extrusion

+Please read the README.md for slicer settings guide

+

+"""

+

+class InfillType(Enum):

+ """Enum for infill type."""

+

+ SMALL_SEGMENTS = 1 # infill with small segments like honeycomb or gyroid

+ LINEAR = 2 # linear infill like rectilinear or triangles

+

+class Slicer(Enum):

+ """Enum for slicer"""

+

+ SEARCH = 0 # for search slicer feature

+ ORCA = 1 # if you use a bambulab printer choose Bambu

+ BAMBU = 2

+ PRUSA = 3

+ CURA = 4 # untested

+

+

+Point2D = namedtuple('Point2D', 'x y')

+Segment = namedtuple('Segment', 'point1 point2')

+

+# EDIT this section for your creation parameters

+# if the filenames have the same name the original file will be overwritten

+# names only used if run in IDE

+INPUT_FILE_NAME: str = r"Universal\bunny_orca.gcode"

+OUTPUT_FILE_NAME: str = r"C:\Users\bjans\Downloads\gradinfilltest_res.gcode"

+

+# Warning there is just one file as output from the slicer, which means you can't compare it to the original

+dialog_in_slicer: bool = True # use different parameters inside of the slicer via dialog else the following values are used

+REMOVE_SLICER_INFO: bool = False # remove first line with slicer information for realistic gcode preview only for prusa, orca slicer

+D_F: float = 1.75 # diameter of the filament in mm

+# this setting is only relevant for SMALL_SEGMENTS infill when disabled the infill outside of the GRADIENT_THICKNESS isn't changed

+THIN_INNER_CORE: bool = True

+# automatically search for the slicer with: Slicer.SEARCH

+Slicer_Type: Slicer = Slicer.SEARCH # if manually assigned and you use a bambulab printer with Orca slicer choose Bambu!

+

+MAX_FLOW: float = 220.0 # maximum extrusion flow

+MIN_FLOW: float = 70.0 # minimum extrusion flow

+GRADIENT_THICKNESS: float = 12.0 # thickness of the gradient (max to min) in mm

+GRADIENT_DISCRETIZATION: float = 4.0 # only applicable for linear infills; number of segments within the

+# gradient(segmentLength=gradientThickness / gradientDiscretization); use sensible values to not overload the printer

+

+# End edit

+

+

+class Section(Enum):

+ """Enum for section type."""

+

+ NOTHING = 0

+ INNER_WALL = 1

+ INFILL = 2

+

+# fine

+def dist(segment: Segment, point: Point2D) -> float:

+ """Calculate the distance from a point to a line with finite length.

+

+ Args:

+ segment (Segment): line used for distance calculation

+ point (Point2D): point used for distance calculation

+

+ Returns:

+ float: distance between ``segment`` and ``point``

+ """

+ px = segment.point2.x - segment.point1.x

+ py = segment.point2.y - segment.point1.y

+ norm = px * px + py * py

+ try:

+ u = ((point.x - segment.point1.x) * px + (point.y - segment.point1.y) * py) / float(norm)

+ except ZeroDivisionError:

+ # error when norm = 0 machine accuracy

+ return 0

+

+ if u > 1:

+ u = 1

+ elif u < 0:

+ u = 0

+ x = segment.point1.x + u * px

+ y = segment.point1.y + u * py

+ dx = x - point.x

+ dy = y - point.y

+

+ return (dx * dx + dy * dy) ** 0.5

+

+# fine

+def get_points_distance(point1: Point2D, point2: Point2D) -> float:

+ """Calculate the euclidean distance between two points.

+

+ Args:

+ point1 (Point2D): first point

+ point2 (Point2D): second point

+

+ Returns:

+ float: euclidean distance between the points

+ """

+ return ((point1.x - point2.x) ** 2 + (point1.y - point2.y) ** 2) ** 0.5

+

+# changed

+def min_distance_from_segment(segment: Segment, segments: List[Segment], return_seg: bool = False) -> float:

+ """Calculate the minimum distance from the midpoint of ``segment`` to the nearest segment in ``segments``.

+

+ Args:

+ segment (Segment): segment to use for midpoint calculation

+ segments (List[Segment]): segments list

+

+ Returns:

+ float: the smallest distance from the midpoint of ``segment`` to the nearest segment in the list

+ """

+ middlePoint = Point2D((segment.point1.x + segment.point2.x) / 2, (segment.point1.y + segment.point2.y) / 2)

+ min_segment = min(segments, key=lambda s: dist(s, middlePoint))

+ min_value = dist(min_segment, middlePoint)

+ if return_seg:

+ return min_value, min_segment

+ else:

+ return min_value

+

+# use re.compile to make it quicker

+prog_searchX = re.compile(r"X(\d*\.?\d*)")

+prog_searchY = re.compile(r"Y(\d*\.?\d*)")

+

+def getXY(currentLine: str) -> Point2D:

+ """Create a ``Point2D`` object from a gcode line.

+

+ Args:

+ currentLine (str): gcode line

+

+ Raises:

+ SyntaxError: when the regular expressions cannot find the relevant coordinates in the gcode

+

+ Returns:

+ Point2D: the parsed coordinates

+ """

+ #searchX = re.search(r"X(\d*\.?\d*)", currentLine)

+ #searchY = re.search(r"Y(\d*\.?\d*)", currentLine)

+

+ searchX = prog_searchX.search(currentLine)

+ searchY = prog_searchY.search(currentLine)

+

+ if searchX and searchY:

+ elementX = searchX.group(1)

+ elementY = searchY.group(1)

+ else:

+ raise SyntaxError(f'Gcode file parsing error for line {currentLine}')

+

+

+ return Point2D(float(elementX), float(elementY))

+

+

+def mapRange(a: Tuple[float, float], b: Tuple[float, float], s: float) -> float:

+ """Calculate a multiplier for the extrusion value from the distance to the perimeter.

+

+ Args:

+ a (Tuple[float, float]): a tuple containing:

+ - a1 (float): the minimum distance to the perimeter (always zero at the moment)

+ - a2 (float): the maximum distance to the perimeter where the interpolation is performed

+ b (Tuple[float, float]): a tuple containing:

+ - b1 (float): the maximum flow as a fraction

+ - b2 (float): the minimum flow as a fraction

+ s (float): the euclidean distance from the middle of a segment to the nearest perimeter

+

+ Returns:

+ float: a multiplier for the modified extrusion value

+ """

+ (a1, a2), (b1, b2) = a, b

+

+ return b1 + ((s - a1) * (b2 - b1) / (a2 - a1))

+

+

+def get_extrusion_command(x: float, y: float, extrusion: float) -> str:

+ """Format a gcode string from the X, Y coordinates and extrusion value.

+

+ Args:

+ x (float): X coordinate

+ y (float): Y coordinate

+ extrusion (float): Extrusion value

+

+ Returns:

+ str: Gcode line

+ """

+ return "G1 X{} Y{} E{}\n".format(round(x, 3), round(y, 3), round(extrusion, 5))

+

+# changed

+def is_begin_layer_line(line: str) -> bool:

+ """Check if current line is the start of a layer section.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is the start of a layer section

+ """

+ if Slicer_Type == Slicer.ORCA or Slicer_Type == Slicer.PRUSA:

+ return line.startswith(";LAYER_CHANGE")

+ elif Slicer_Type == Slicer.BAMBU:

+ return line.startswith("; CHANGE_LAYER")

+ elif Slicer_Type == Slicer.CURA:

+ return line.startswith(";LAYER:")

+

+

+# changed

+def is_begin_inner_wall_line(line: str) -> bool:

+ """Check if current line is the start of an inner wall section.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is the start of an inner wall section

+ """

+ if Slicer_Type == Slicer.ORCA:

+ return line.startswith(";TYPE:Inner wall")

+ elif Slicer_Type == Slicer.PRUSA:

+ return line.startswith(";TYPE:Perimeter")

+ elif Slicer_Type == Slicer.BAMBU:

+ return line.startswith("; FEATURE: Inner wall")

+ elif Slicer_Type == Slicer.CURA:

+ return line.startswith(";TYPE:WALL-INNER")

+

+

+# changed

+def is_end_inner_wall_line(line: str) -> bool: #TODO delete?

+ """Check if current line is the start of an outer wall section.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is the start of an outer wall section

+ """

+ if Slicer_Type == Slicer.ORCA:

+ return line.startswith(";TYPE:Outer wall")

+ elif Slicer_Type == Slicer.PRUSA:

+ return line.startswith(";TYPE:External perimeter")

+ elif Slicer_Type == Slicer.BAMBU:

+ return line.startswith("; FEATURE: Outer wall")

+ elif Slicer_Type == Slicer.CURA:

+ return line.startswith(";TYPE:WALL-OUTER")

+

+

+# fine

+def is_extrusion_line(line: str) -> bool:

+ """Check if current line is a standard printing segment.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is a standard printing segment

+ """

+ return "G1" in line and " X" in line and "Y" in line and "E" in line

+

+# changed

+def is_begin_infill_segment_line(line: str) -> bool:

+ """Check if current line is the start of an infill.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is the start of an infill section

+ """

+ if Slicer_Type == Slicer.ORCA:

+ return line.startswith(";TYPE:Sparse infill")

+ elif Slicer_Type == Slicer.PRUSA:

+ return line.startswith(";TYPE:Internal infill")

+ elif Slicer_Type == Slicer.BAMBU:

+ return line.startswith("; FEATURE: Sparse infill")

+ elif Slicer_Type == Slicer.CURA:

+ return line.startswith(";TYPE:FILL")

+

+def is_start_gcode(line: str)-> bool:

+ """Check if current line indicates start gcode.

+

+ Args:

+ line (str): Gcode line

+

+ Returns:

+ bool: True if the line is the start gcode

+ """

+ if Slicer_Type == Slicer.ORCA or Slicer_Type == Slicer.PRUSA:

+ return line.startswith(";TYPE:Custom")

+ elif Slicer_Type == Slicer.BAMBU:

+ return line.startswith("; FEATURE: Custom")

+ elif Slicer_Type == Slicer.CURA:

+ return False #TODO

+ #return line.startswith(";Generated with Cura_SteamEngine")

+

+def control_flow(hotend_max_flow: float, extrusionLength:float, distance:float, d_f:float)-> str:

+ """Calculate new feedrate to stay at the limit of the hotend maximum flow.

+

+ Args:

+ hotend_max_flow (float): maximum volumetric flow of the hotend in mm^3/s

+ extrusionLength (float): length of the extruded filament (E value) in mm

+ distance (float): distance of the extrusion in mm

+ d_f (float): diameter of the filament in mm

+ current_flow (float): current flow value in mm^3/s

+

+ Returns:

+ str: Gcode line with new feedrate

+ """

+ F = round((hotend_max_flow*distance*60*4)/(extrusionLength*(d_f**2)*pi), 3)

+ return "G1 F{}\n".format(F)

+

+def is_collinear(wall:Segment, p_0:Point2D, p_1:Point2D)->bool:

+ """ Check if the infill segment is nearly collinear with the wall segment.

+ Args:

+ wall (Segment): The wall segment represented by two points (point1 and point2).

+ p_0 (Point2D): The starting point of the infill segment.

+ p_1 (Point2D): The ending point of the infill segment.

+ Returns:

+ bool: True if the infill segment is collinear with the wall segment

+ """

+ def clamp(value, min_value, max_value)-> float:

+ return max(min(value, max_value), min_value)

+ try:

+ v_wall = Point2D(wall.point2.x - wall.point1.x, wall.point2.y - wall.point1.y)

+ norm_wall = Point2D(*(1 / get_points_distance(wall.point1, wall.point2) * v for v in (v_wall.x, v_wall.y)))

+ v_infill = Point2D(p_1.x - p_0.x, p_1.y - p_0.y)

+ norm_infill = Point2D(*((1 / get_points_distance(p_0, p_1)) * v for v in v_infill))

+ neg_norm_infill = Point2D(*((-1) * v for v in norm_infill))

+

+ dot_product = norm_wall.x * norm_infill.x + norm_wall.y * norm_infill.y

+ neg_dot_product = norm_wall.x * neg_norm_infill.x + norm_wall.y * neg_norm_infill.y

+ # add boundries

+ dot_product = clamp(dot_product, -1, 1)

+ neg_dot_product = clamp(neg_dot_product, -1, 1)

+

+ angle = min(abs(degrees(acos(dot_product))), abs(degrees(acos(neg_dot_product))))

+ except ZeroDivisionError:

+ angle = 0

+ return angle < 15

+

+lines = []

+# change to use search patterns instead of finding elements in string

+def process_gcode(

+ input_file_name: str,

+ output_file_name: str,

+ max_flow: float,

+ min_flow: float,

+ gradient_thickness: float,

+ gradient_discretization: float,

+ d_f: float,

+ thin_inner_core: bool,

+) -> None:

+ """Parse input Gcode file and modify infill portions with an extrusion width gradient."""

+ global currentLine, Slicer_Type

+ prog_move = re.compile(r'^G[0-1].*X.*Y')

+ prog_extrusion = re.compile(r'^G1.*X.*Y.*E')

+ if Slicer_Type == Slicer.BAMBU:

+ prog_type = re.compile(r'^; FEATURE:')

+ else:

+ prog_type = re.compile(r'^;TYPE:')

+

+ edit = 0

+ ignore_pos = True

+ is_old_speed = False

+ currentSection = Section.NOTHING

+ lastPosition = Point2D(-float('inf'), -float('inf')) # set infinate start point

+ gradientDiscretizationLength = gradient_thickness / gradient_discretization

+ small_segments_infill_type = ['gyroid', 'honeycomb', '3dhoneycomb'] # list of all small segments infill types

+

+ with open(input_file_name, "r") as gcodeFile:

+ gcode = gcodeFile.readlines()

+ found_flow = False

+ found_infill_type = False

+ # find the volumetric flow limit of the filament from slicer settings (probaly not compatible with cura) and reversing isn't optimal for bambu

+ for line in reversed(gcode):

+ if line.startswith('; filament_max_volumetric_speed ='):

+ hotend_max_flow = min(map(float, line.split('=')[-1].split(','))) # different filaments are sperated by , minimum is used

+ print(f'Maximum flow is: {hotend_max_flow} [mm^3/s]')

+ found_flow = True

+ if line.startswith('; fill_pattern = ') or line.startswith('; sparse_infill_pattern = '):

+ infill_type = line.split('=')[-1].strip().split()[0]

+ if infill_type in small_segments_infill_type:

+ infill_type = InfillType.SMALL_SEGMENTS

+ else:

+ infill_type = InfillType.LINEAR

+ found_infill_type = True

+ if all((found_infill_type, found_flow)):

+ print(infill_type)

+ break # task finished

+

+ for currentLine in gcode:

+ # find the slicer automatically

+ if Slicer_Type == Slicer.SEARCH:

+ if currentLine.startswith("; generated by PrusaSlicer"):

+ Slicer_Type = Slicer.PRUSA

+ prog_type = re.compile(r'^;TYPE:')

+ if REMOVE_SLICER_INFO:

+ continue # delete first line due to incorrect gcode preview

+

+ elif currentLine.startswith("; BambuStudio"):

+ Slicer_Type = Slicer.BAMBU

+ prog_type = re.compile(r'^; FEATURE:')

+

+ elif currentLine.startswith(";Generated with Cura_SteamEngine"):

+ Slicer_Type = Slicer.CURA

+ prog_type = re.compile(r'^;TYPE:')

+

+ elif currentLine.startswith("; generated by OrcaSlicer"):

+ Slicer_Type = Slicer.ORCA

+ prog_type = re.compile(r'^;TYPE:')

+ if REMOVE_SLICER_INFO:

+ continue # delete first line due to incorrect gcode preview

+

+ # check if Orca slicer with bambu printer

+ if Slicer_Type == Slicer.ORCA and currentLine.startswith("; printer_model = Bambu"):

+ Slicer_Type = Slicer.BAMBU

+ prog_type = re.compile(r'^; FEATURE:')

+

+ # get line width to determine critical zone next to wall

+ if currentLine.startswith("; infill extrusion width = ") or currentLine.startswith("; sparse_infill_line_width = "):

+ infill_linewidth = float(currentLine.split("=")[-1].split("mm")[0])

+ if currentLine.startswith("; perimeters extrusion width = ") or currentLine.startswith("; inner_wall_line_width = "):

+ inner_wall_linewidth = float(currentLine.split("=")[-1].split("mm")[0])

+

+ writtenToFile = 0

+

+ if is_begin_layer_line(currentLine):

+ perimeterSegments = []

+

+ # search if it indicates a type

+ if prog_type.search(currentLine):

+ if Slicer_Type == Slicer.SEARCH:

+ raise SyntaxError("Slicer not found.")

+

+ # ignore start or end gcode

+ ignore_pos = is_start_gcode(currentLine)

+

+ if is_begin_inner_wall_line(currentLine):

+ currentSection = Section.INNER_WALL

+ elif is_begin_infill_segment_line(currentLine):

+ currentSection = Section.INFILL

+ # irrelevent type, this was in the cura version searching for ; at the end

+ else:

+ currentSection = Section.NOTHING

+

+ # write to file and continue

+ lines.append(currentLine)

+ continue

+

+ elif currentLine.startswith('G2 ') or currentLine.startswith('G3 '):

+ raise TypeError("G2/3 commands aren't supported! Disable Arc fitting in your slicer")

+

+ if currentSection == Section.INNER_WALL and is_extrusion_line(currentLine):

+ perimeterSegments.append(Segment(getXY(currentLine), lastPosition))

+

+ if currentSection == Section.INFILL:

+ if "F" in currentLine and "G1" in currentLine:

+ searchSpeed = re.search(r"F(\d*\.?\d*)", currentLine)

+ if searchSpeed:

+ infill_speed = searchSpeed.group(1)

+ infill_begin = True

+ # previous double F command fixed

+ if "E" in currentLine:

+ lines.append("G1 F{}\n".format(infill_speed))

+ else:

+ raise SyntaxError(f'Gcode file parsing error for line {currentLine}')

+ if prog_extrusion.search(currentLine):

+ currentPosition = getXY(currentLine)

+ splitLine = currentLine.split(" ")

+

+ if infill_type == InfillType.LINEAR:

+ # find extrusion length

+ for element in splitLine:

+ if "E" in element:

+ extrusionLength = float(element[1:])

+ segmentLength = get_points_distance(lastPosition, currentPosition)

+ segmentSteps = segmentLength / gradientDiscretizationLength

+ extrusionLengthPerSegment = extrusionLength / segmentSteps

+ segmentDirection = Point2D(

+ (currentPosition.x - lastPosition.x) / segmentLength * gradientDiscretizationLength,

+ (currentPosition.y - lastPosition.y) / segmentLength * gradientDiscretizationLength,

+ )

+ # calculate original infill flow once per layer TODO might lead to issue with multiple objects with different settings

+ if infill_begin:

+ infill_flow = (float(infill_speed)*(d_f**2)*pi*extrusionLength) / (4*segmentLength*60)

+ infill_begin = False

+

+ if segmentSteps >= 2:

+ for _ in range(int(segmentSteps)):

+ segmentEnd = Point2D(

+ lastPosition.x + segmentDirection.x, lastPosition.y + segmentDirection.y

+ )

+ shortestDistance = min_distance_from_segment(

+ Segment(lastPosition, segmentEnd), perimeterSegments

+ )

+ if shortestDistance < gradient_thickness:

+ flow_factor = mapRange(

+ (0, gradient_thickness), (max_flow / 100, min_flow / 100), shortestDistance

+ )

+ segmentExtrusion = extrusionLengthPerSegment * flow_factor

+

+ else:

+ segmentExtrusion = extrusionLengthPerSegment * min_flow / 100

+ flow_factor = min_flow / 100

+

+ # check for flow limit

+ current_flow = infill_flow * flow_factor

+ if current_flow > hotend_max_flow:

+ new_feedrate = control_flow(hotend_max_flow, extrusionLengthPerSegment*flow_factor, gradientDiscretizationLength, d_f)

+ lines.append(new_feedrate + get_extrusion_command(segmentEnd.x, segmentEnd.y, segmentExtrusion))

+ is_old_speed = False

+ elif is_old_speed:

+ lines.append(get_extrusion_command(segmentEnd.x, segmentEnd.y, segmentExtrusion))

+ else:

+ is_old_speed = True

+ lines.append("G1 F{}\n".format(infill_speed) + get_extrusion_command(segmentEnd.x, segmentEnd.y, segmentExtrusion))

+

+ lastPosition = segmentEnd

+ # MissingSegment

+ segmentLengthRatio = get_points_distance(lastPosition, currentPosition) / segmentLength

+ current_flow = infill_flow * max_flow / 100

+ if current_flow > hotend_max_flow:

+ new_feedrate = control_flow(hotend_max_flow, extrusionLength * max_flow / 100, segmentLength, d_f)

+

+ lines.append(new_feedrate +

+ get_extrusion_command(

+ currentPosition.x,

+ currentPosition.y,

+ segmentLengthRatio * extrusionLength * max_flow / 100,

+ )

+ )

+ else:

+ lines.append(

+ get_extrusion_command(

+ currentPosition.x,

+ currentPosition.y,

+ segmentLengthRatio * extrusionLength * max_flow / 100,

+ )

+ )

+ else: # not splitted line

+ outPutLine = ""

+ for element in splitLine:

+ if "E" in element:

+ outPutLine = outPutLine + "E" + str(round(extrusionLength * max_flow / 100, 5))

+ current_flow = infill_flow * max_flow / 100

+ else:

+ outPutLine = outPutLine + element + " "

+

+ if current_flow > hotend_max_flow:

+ new_feedrate = control_flow(hotend_max_flow, extrusionLength * max_flow / 100, segmentSteps, d_f)

+ outPutLine = new_feedrate + outPutLine + "\n"

+ else:

+ outPutLine = outPutLine + "\n"

+ lines.append(outPutLine)

+ writtenToFile = 1

+

+ # gyroid or 3d/honeycomb

+ if infill_type == InfillType.SMALL_SEGMENTS:

+ seg_info = min_distance_from_segment(

+ Segment(lastPosition, currentPosition), perimeterSegments, return_seg=True

+ )

+ shortestDistance = seg_info[0]

+ min_seg = seg_info[1]

+ collinear = is_collinear(min_seg, lastPosition, currentPosition)

+

+ outPutLine = ""

+ if shortestDistance < gradient_thickness:

+ for element in splitLine:

+ if "E" in element:

+ flow_factor = mapRange(

+ (0, gradient_thickness), (max_flow / 100, min_flow / 100), shortestDistance

+ )

+ # prevent unclean extrusion near the wall

+ critical_distance = (infill_linewidth + inner_wall_linewidth) * 1.4 / 2

+ if shortestDistance <= critical_distance and collinear:

+ flow_factor = 1

+ newE = float(element[1:]) * flow_factor

+ # calculate original infill flow once per layer

+ if infill_begin:

+ segmentLength = get_points_distance(lastPosition, currentPosition)

+ infill_flow = (float(infill_speed)*(d_f**2)*pi*float(element[1:])) / (4*segmentLength*60)

+ infill_begin = False

+

+ if infill_flow > hotend_max_flow + 0.5: #TODO delete? will trigger if wrong max flow is set only happens with two filaments

+ print('Your infill flow is higher, than the hotend limit in the script!')

+ print('Please adjust either your slicer or script settings')

+ print('Slicer Infill Flow:', infill_flow, 'Script Hotend Max Flow:', hotend_max_flow, '[mm^3/s]')

+ input()

+

+ outPutLine = outPutLine + "E" + str(round(newE, 5))

+ else:

+ outPutLine = outPutLine + element + " "

+ current_flow = infill_flow * flow_factor

+ if current_flow > hotend_max_flow:

+ segmentLength = get_points_distance(lastPosition, currentPosition)

+ new_feedrate = control_flow(hotend_max_flow, newE, segmentLength, d_f)

+ is_old_speed = False

+

+ outPutLine = new_feedrate + outPutLine + "\n"

+

+ elif is_old_speed:

+ outPutLine = outPutLine + "\n"

+ else:

+ is_old_speed = True

+ outPutLine = "G1 F{}\n".format(infill_speed) + outPutLine + "\n"

+

+ lines.append(outPutLine)

+ writtenToFile = 1

+

+ elif thin_inner_core:

+ # no need to check for maximum flow since it will be lowered

+ for element in splitLine:

+ if "E" in element:

+ newE = float(element[1:]) * min_flow / 100

+ outPutLine = outPutLine + "E" + str(round(newE, 5)) + "\n"

+ else:

+ outPutLine = outPutLine + element + " "

+

+ lines.append(outPutLine)

+ writtenToFile = 1

+

+

+ # line with move

+ if prog_move.search(currentLine) and not ignore_pos:

+ lastPosition = getXY(currentLine)

+

+ # write uneditedLine

+ if writtenToFile == 0:

+ lines.append(currentLine)

+ else:

+ edit += 1

+

+ with open(output_file_name, "w") as outputFile:

+ for line in lines:

+ outputFile.write("%s" % line)

+

+ # check if the script did anything

+ if edit == 0:

+ print('No changes were made to the file!')

+ print('Is this the right slicer?', Slicer_Type)

+ print('if you use Orca slicer with a Bambu printer it should be BAMBU')

+

+ if run_in_slicer:

+ print('Press enter and check the script')

+ input()

+

+

+if __name__ == '__main__':

+ try:

+ # when more than one argument is parsed it's run by slicer

+ run_in_slicer = len(sys.argv) > 1

+

+ if run_in_slicer:

+ file_path = sys.argv[1] # the path of the gcode given by the slicer

+ if dialog_in_slicer:

+ # repeat process up to 3 times if inserted values are incorrect

+ for _ in range(3):

+ print('script called:', sys.argv[0],'\n')

+ print('Use default values (declared in the script)? [y] to proceed')

+ default = str(input())

+ if default == 'y':

+ print('Script is running please wait...')

+ break

+

+ print('Input MAX_FLOW and press enter (default 350)')

+ MAX_FLOW = int(input())

+

+ print('Input MIN_FLOW and press enter (default 50)')

+ MIN_FLOW = int(input())

+

+ print('Input GRADIENT_THICKNESS and press enter (default 6.0)')

+ GRADIENT_THICKNESS = float(input())

+

+ print('Input INFILL_TYPE choose [0] for SMALL_SEGMENTS and [1] for LINEAR:')

+ choose_infill_type = int(input()) #TODO update and find solution inside main program after finding infill type?

+ if choose_infill_type == 0:

+ INFILL_TYPE = InfillType.SMALL_SEGMENTS

+ print('Enable THIN_INNER_CORE ? [y] to enable')

+ if str(input()) == 'y':

+ THIN_INNER_CORE = True

+ else:

+ THIN_INNER_CORE = False

+ else:

+ INFILL_TYPE = InfillType.LINEAR

+ print('Input GRADIENT_DISCRETIZATION and press enter (default 4.0)')

+ GRADIENT_DISCRETIZATION = float(input())

+

+ print('Are all values correct? [y] to proceed')

+ correct = str(input())

+

+ if correct == 'y':

+ print('Script is running please wait...')

+ break

+ start = time.time()

+ # changed out path

+ process_gcode(

+ file_path, file_path, MAX_FLOW, MIN_FLOW, GRADIENT_THICKNESS, GRADIENT_DISCRETIZATION, D_F, THIN_INNER_CORE

+ )

+

+ else:

+ start = time.time()

+ process_gcode(

+ INPUT_FILE_NAME, OUTPUT_FILE_NAME, MAX_FLOW, MIN_FLOW, GRADIENT_THICKNESS, GRADIENT_DISCRETIZATION, D_F, THIN_INNER_CORE

+ )

+

+ print('Time to excecute:',time.time()- start)

+

+ except Exception:

+ traceback.print_exc()

+

+ print('currentLine:', currentLine)

+ print('Press enter to close window')

+ print('Is this the right slicer?', Slicer_Type)

+ print('if you use Orca slicer with a Bambu printer it should be BAMBU')

+ print('If you need help open an issue on my Github at: https://github.com/WatchingWatches/GradientInfill')

+ print('Please share a .3mf file with all of the settings you were using and the error message')

+

+ if run_in_slicer:

+ input()

\ No newline at end of file

+

+  +

+ +

+### Unclean extrusion:

+

+Often times Infill generates lines, which look like perimeters. The problem is, that there is no space for the line to expand to, like in the core of the Infill.

+This results in unclean extrusions, which have an increased height, which results in marks on the top layers. To fix this, lines which are nearly collinear to the perimeter (small angle) don't get modified and stay at their original width.

+The feature currently only works with `SMALL_SEGMENTS`.

+

+

+

+### Unclean extrusion:

+

+Often times Infill generates lines, which look like perimeters. The problem is, that there is no space for the line to expand to, like in the core of the Infill.

+This results in unclean extrusions, which have an increased height, which results in marks on the top layers. To fix this, lines which are nearly collinear to the perimeter (small angle) don't get modified and stay at their original width.

+The feature currently only works with `SMALL_SEGMENTS`.

+

+ +

+  +

+