Replies: 11 comments 41 replies

-

|

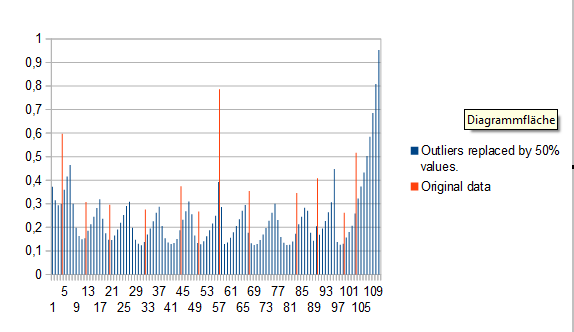

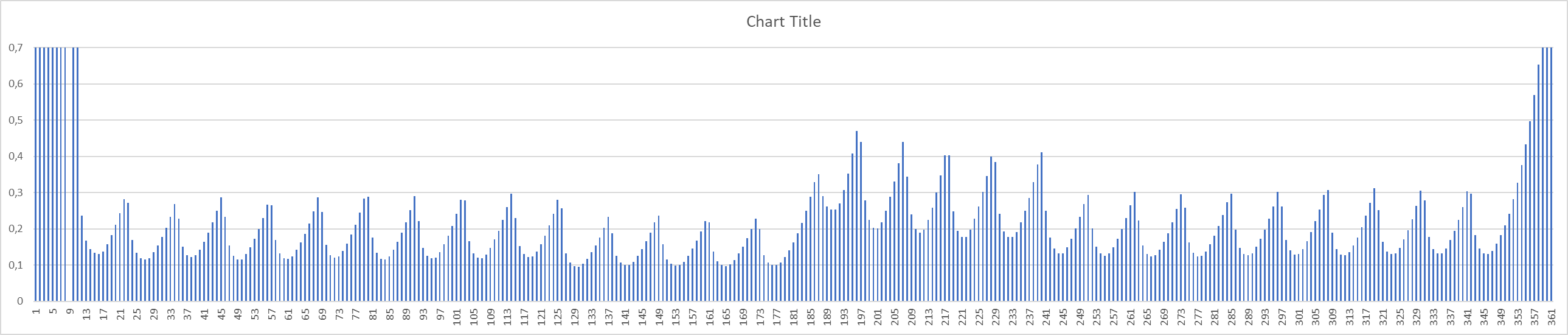

That looks better but it still misses about 10% of all sensor readings: The red values are twice as high as they should be; most likely because one revolution of the wheel was not read by the sensor and hence it took two revolutions to come up with a value. |

Beta Was this translation helpful? Give feedback.

-

|

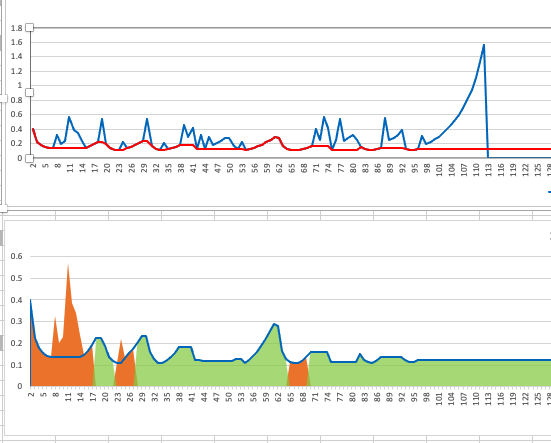

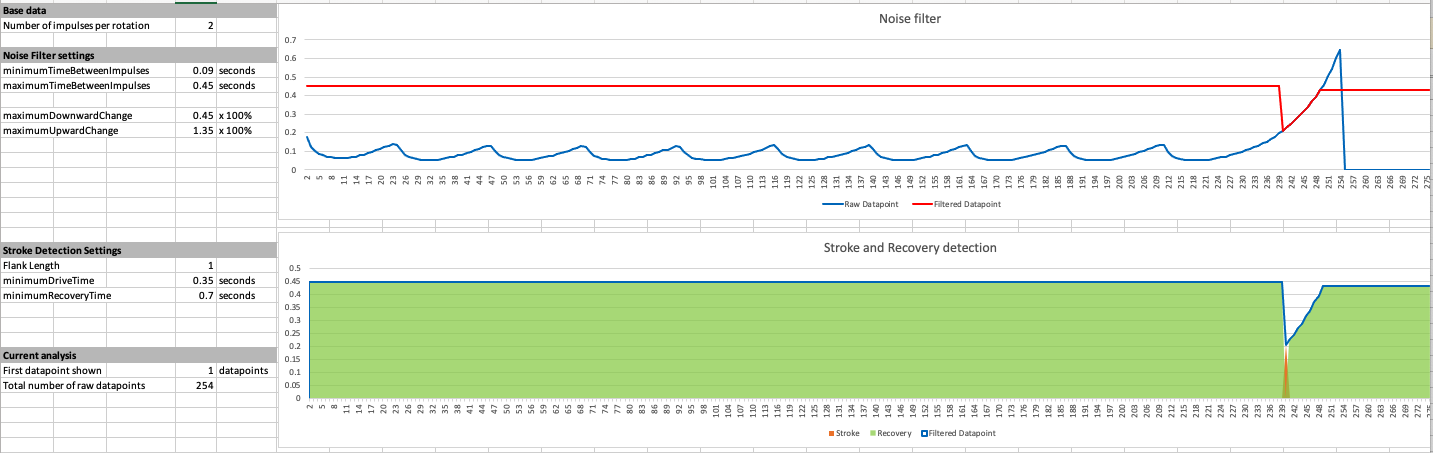

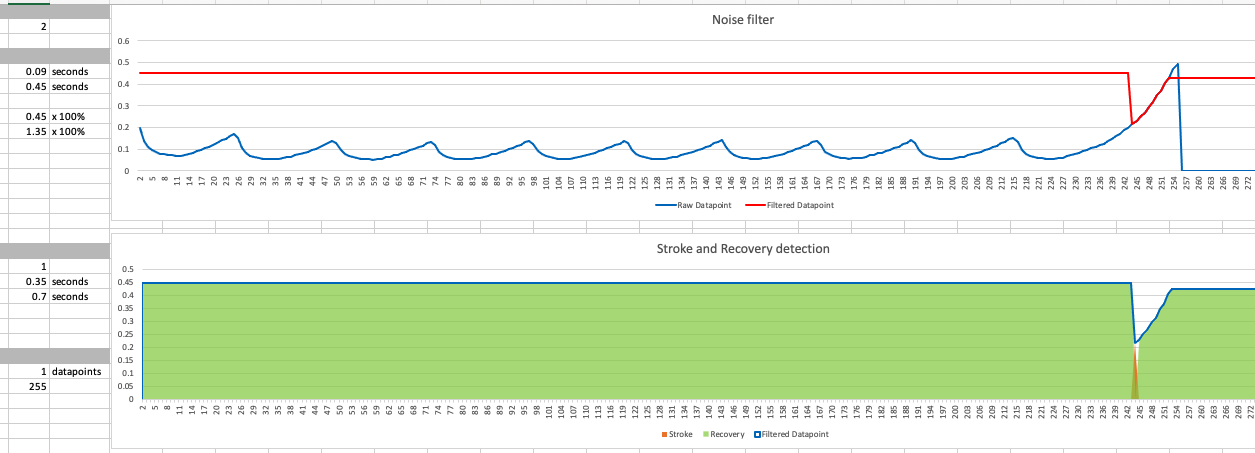

EDIT, as I just saw @Gordon-Shumway2 anwer. Included those in the steps That is good news. I had a look at the data, and it seems that there are missed impulses (those are the upwards spikes). I would try to fine tune the So these are the step I would try (sequential):

You should start every test with the default settings (i.e. when you change the |

Beta Was this translation helpful? Give feedback.

-

|

Ok what should I do with previus step ?

Up side down seams bad.

|

Beta Was this translation helpful? Give feedback.

-

|

Sanity check please.... Looking at this video about reed switches and magnet orientation and assuming that the poles on neodym disc-shaped magnets are on the opposing flat sides -see my brain comes up with a weird setup;

Edit: alternatively (in case a cut would compromise the stability of the wood) you could glue two little blocks of wood to one side of the wooden part and squeeze the magnet in between. That should match the setup outlined in the video above at 04:33. @luca-219, please do not try this yet. It seems strange and @Abasz certainly has more experience with reed switches than I have. |

Beta Was this translation helpful? Give feedback.

-

|

Exactly. At 6:50 I think was my condition before I turned 90’ my reed. And

after that 0.00x disappear.

|

Beta Was this translation helpful? Give feedback.

-

|

I turned my reed and positioned beside the magnet rather than the middle. |

Beta Was this translation helpful? Give feedback.

-

|

@JaapvanEkris I have a quick question re. If I set it to What I dont understand is that my expectation with such a high The settings are default except for these: rowerSettings: {

numOfImpulsesPerRevolution: 1,

sprocketRadius: 1.55,

minimumTimeBetweenImpulses: 0.007,

smoothing: 1,

flankLength: 6,

minumumForceBeforeStroke: 2,

minimumStrokeQuality: 1,

minimumDriveTime: 0.200, // minimum time of the drive phase

minimumRecoveryTime: 0.600, // minimum time of the recovery phase

dragFactor: 108,

autoAdjustDragFactor: true,

dragFactorSmoothing: 1,

minimumDragQuality: 0.95,

flywheelInertia: 0.08,

maximumStrokeTimeBeforePause: 6.0

} |

Beta Was this translation helpful? Give feedback.

-

|

I can't stay with this new fantastic performance monitor without use all functionality :-) |

Beta Was this translation helpful? Give feedback.

-

|

thank you, my error now is fixed |

Beta Was this translation helpful? Give feedback.

-

|

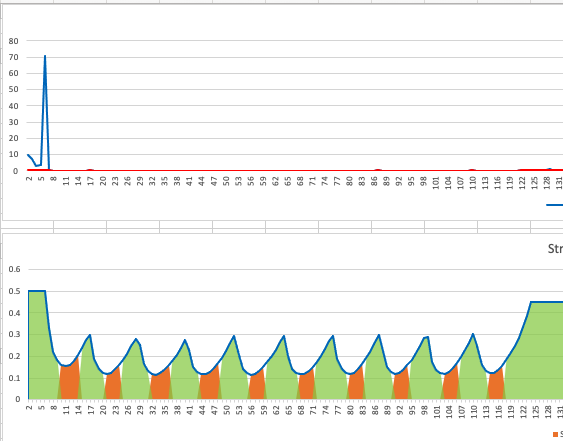

In my opinion all work fine and I'm going to close setting. }, and result |

Beta Was this translation helpful? Give feedback.

-

|

I read the document , but I have a doubt 1700 could be a valid value? I sow

in ather setting Numbers between 100/150 , 1700 what do you think?

|

Beta Was this translation helpful? Give feedback.

Uh oh!

There was an error while loading. Please reload this page.

Uh oh!

There was an error while loading. Please reload this page.

-

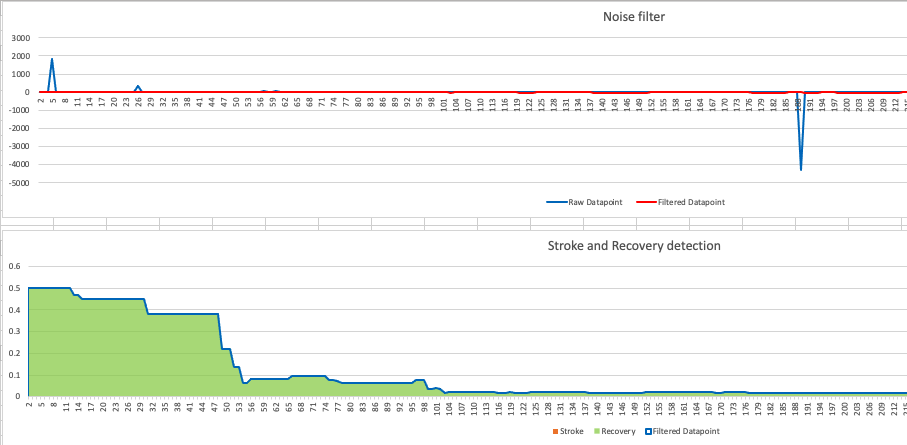

After all your suggestions in previus topick I got a stable result. (seems)

I use small neodymium magnet and I turn 90° reed sensor (image below).

Stable result.

2023-01-31_16-39-55_raw.csv

gpioMinimumPulseLength: 120,

rowerSettings: {

numOfImpulsesPerRevolution: 1,

sprocketRadius: 1.55,

minimumTimeBetweenImpulses: 0.007,

smoothing: 1,

flankLength: 6,

minumumForceBeforeStroke: 2,

minimumStrokeQuality: 0.6,

minimumDriveTime: 0.200, // minimum time of the drive phase

minimumRecoveryTime: 0.600, // minimum time of the recovery phase

dragFactor: 108,

autoAdjustDragFactor: true,

dragFactorSmoothing: 1,

minimumDragQuality: 0.97,

flywheelInertia: 0.08,

maximumStrokeTimeBeforePause: 6.0

Beta Was this translation helpful? Give feedback.

All reactions